Simplify Reliability. Amplify Performance

A modern reliability and asset management platform built for small and mid-sized industrial sites. Organize assets, assess equipment criticality, and grow structured reliability programs—without enterprise complexity or cost.

Your Reliability Foundation all in one Place.

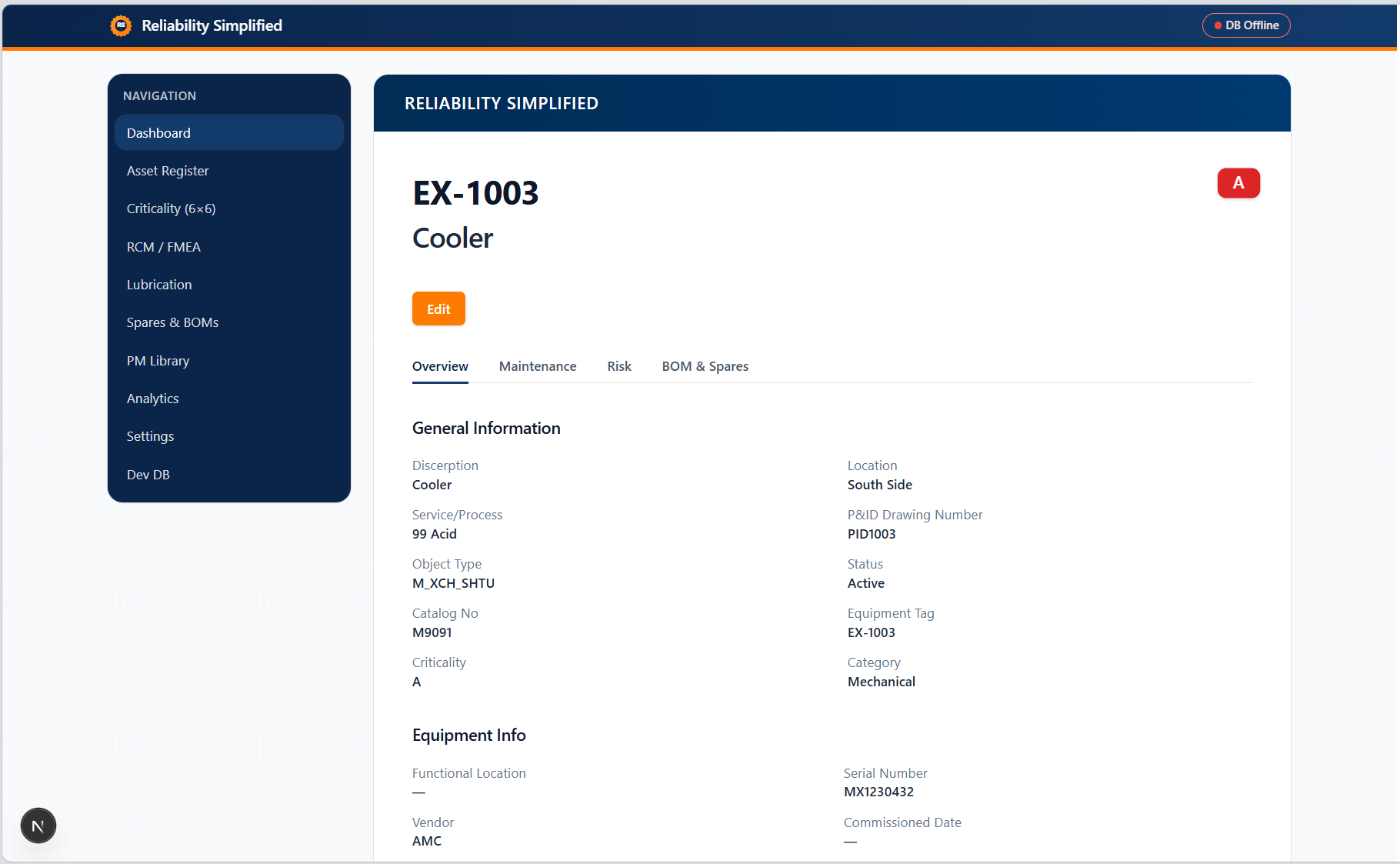

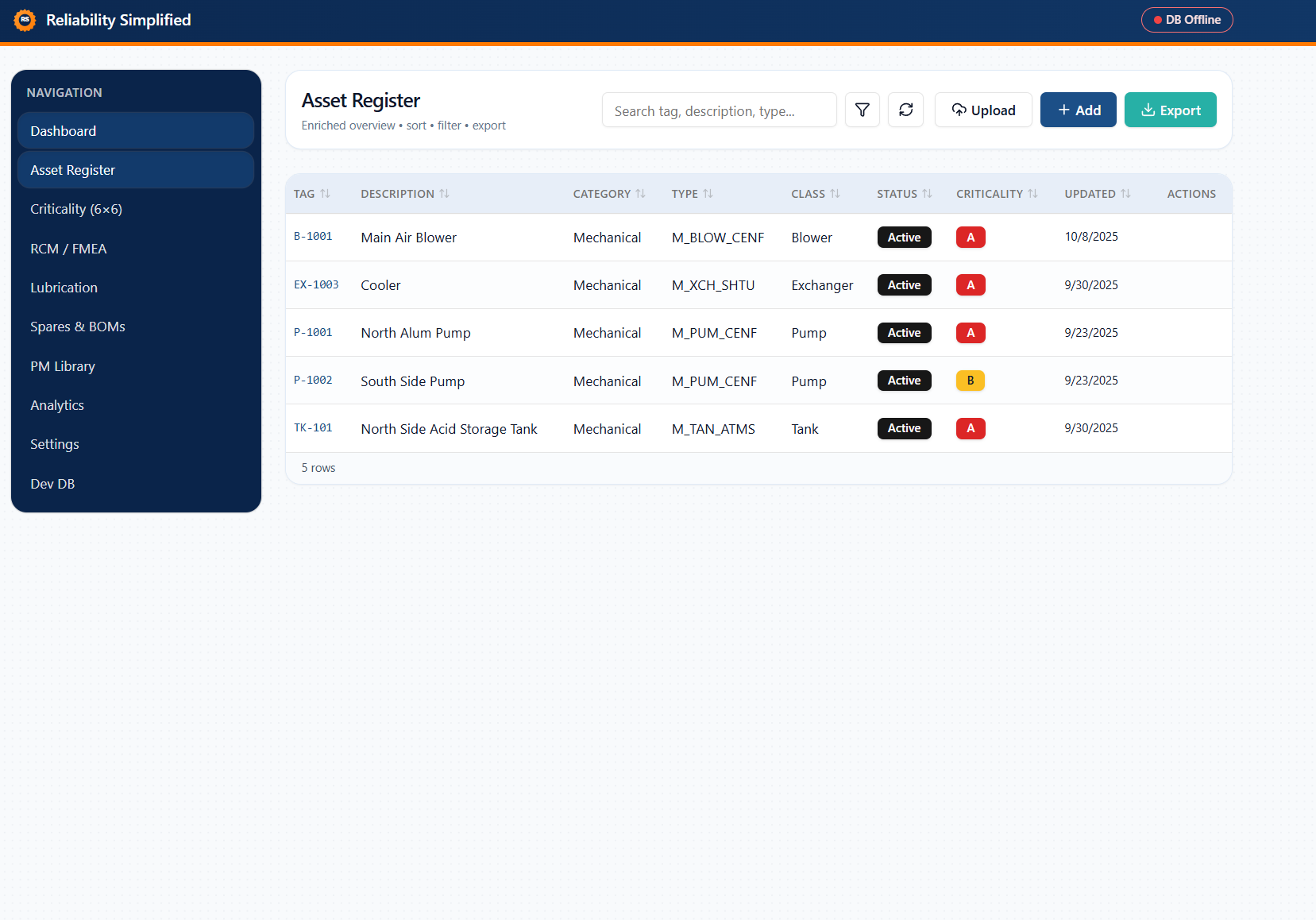

Asset Register

Build a clean, scalable foundation. Bulk import assets from Excel, tag with QR codes, and maintain a single source of truth for every piece of equipment.

Criticality & Risk

Focus on what matters most. Score and visualize equipment risk, no spreadsheets, no guesswork.

Reliability Library

Accelerate improvement with pre-built maintenance strategies.Use ours or add your own.

Equipment Tags

Order laser-engraved equipment tags linked directly to your asset cards. Create instant visibility in the field—scan, view, and update data right from the shop floor.

Reliability Tools Built by Practitioners.

Download maintenance templates, PM checklists, and FMEA worksheets—all designed to help smaller facilities kick-start structured reliability programs.

Reliability Shouldn’t be Complicated or Expensive.

We built Reliability Simplified to bring world-class reliability practices within reach for every facility—without the cost or complexity of enterprise software. Our mission is to help smaller operations start strong, scale confidently, and prove the impact of reliability from day one.

Start Small; Scale Fast.

Import your equipment in minutes with smart templates and guided setup.

Identify what matters most using built-in criticality scoring and heatmaps.

Apply PM templates, lubrication plans, and analytics to drive reliability maturity.

From concept to capability.

Practical examples of how Reliability Simplified supports reliability teams.

Unified visibility in one platform

Import from Excel or tag with QR codes to instantly organize all equipment data—your single source of truth for every asset.

Smarter maintenance prioritization

Quickly score and visualize equipment risk. Focus resources where reliability matters most—no spreadsheets, no guesswork.

Continuous improvement built in

Build FMEA-based PM strategies, track program progress, and evolve your reliability maturity over time.

Latest Insights

Practical lessons and case studies

-

Reliability Culture Starts on the Shop Floor: Why Discipline Beats Technology

The Myth of Technology in Reliability Walk into almost any refinery or chemical plant and you’ll find cutting-edge monitoring systems, advanced sensors, and expensive software platforms. From predictive maintenance dashboards to AI-driven analytics, the tools are everywhere. And yet — downtime persists. Failures still happen. Preventive maintenance…

-

Reliability – The True Cost of Cutting Corners

The False Reliability Economy of “Cheaper Is Better” It happens in plants and refineries around the world every day: a well-meaning procurement team chooses a lower-cost component or a generic spare over the OEM part. This can be the opening act to an expensive—and sometimes catastrophic—reliability failure,…