Build a reliability program that actually sticks.

We help industrial teams standardize asset structure, prioritize critical equipment, and implement proven reliability practices—using our software platform and optional hands-on consulting.

No CMMS replacement. We complement the tools you already use and focus on reliability structure, prioritization, and decision-making.

Choose your path: software, consulting, or both.

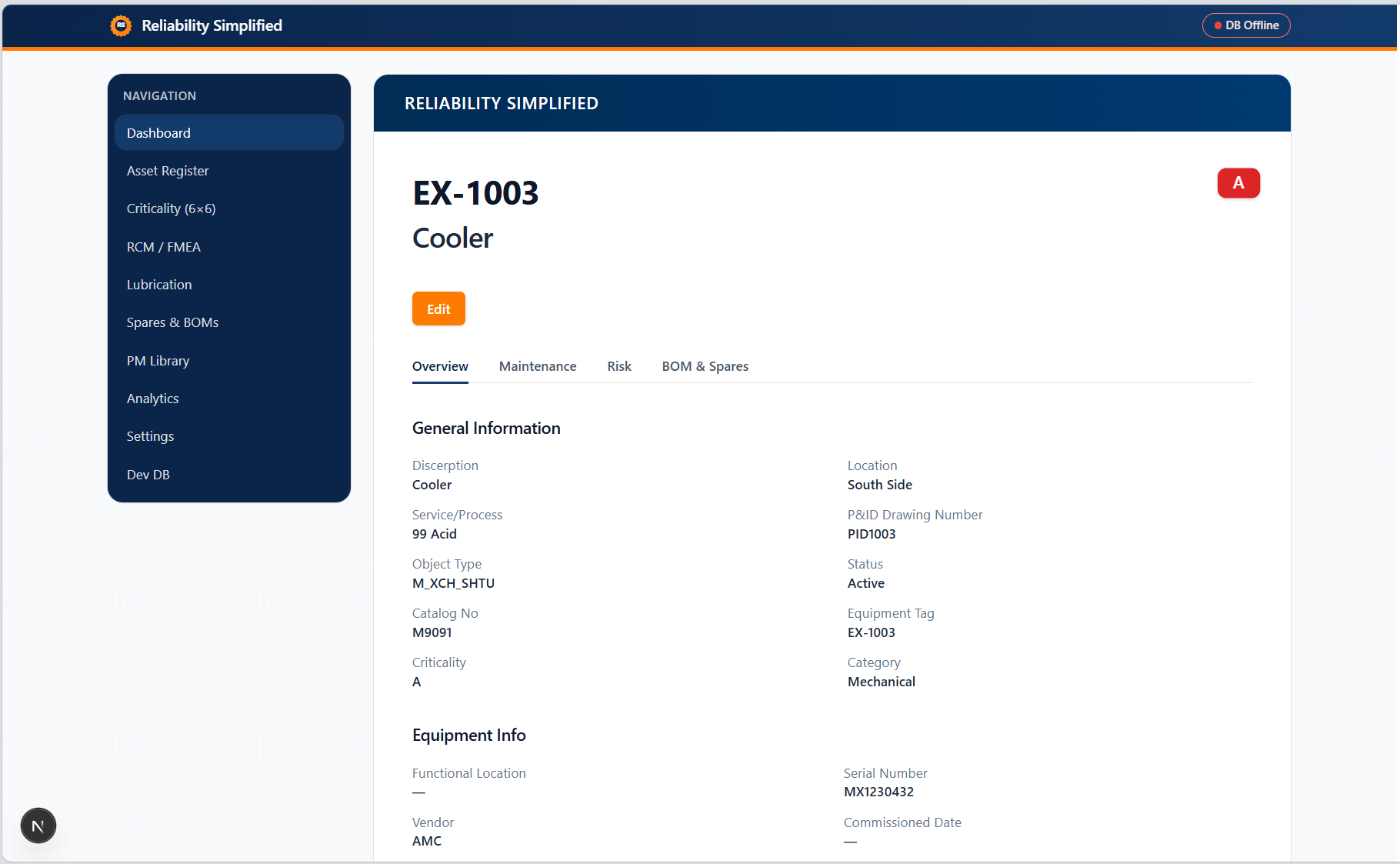

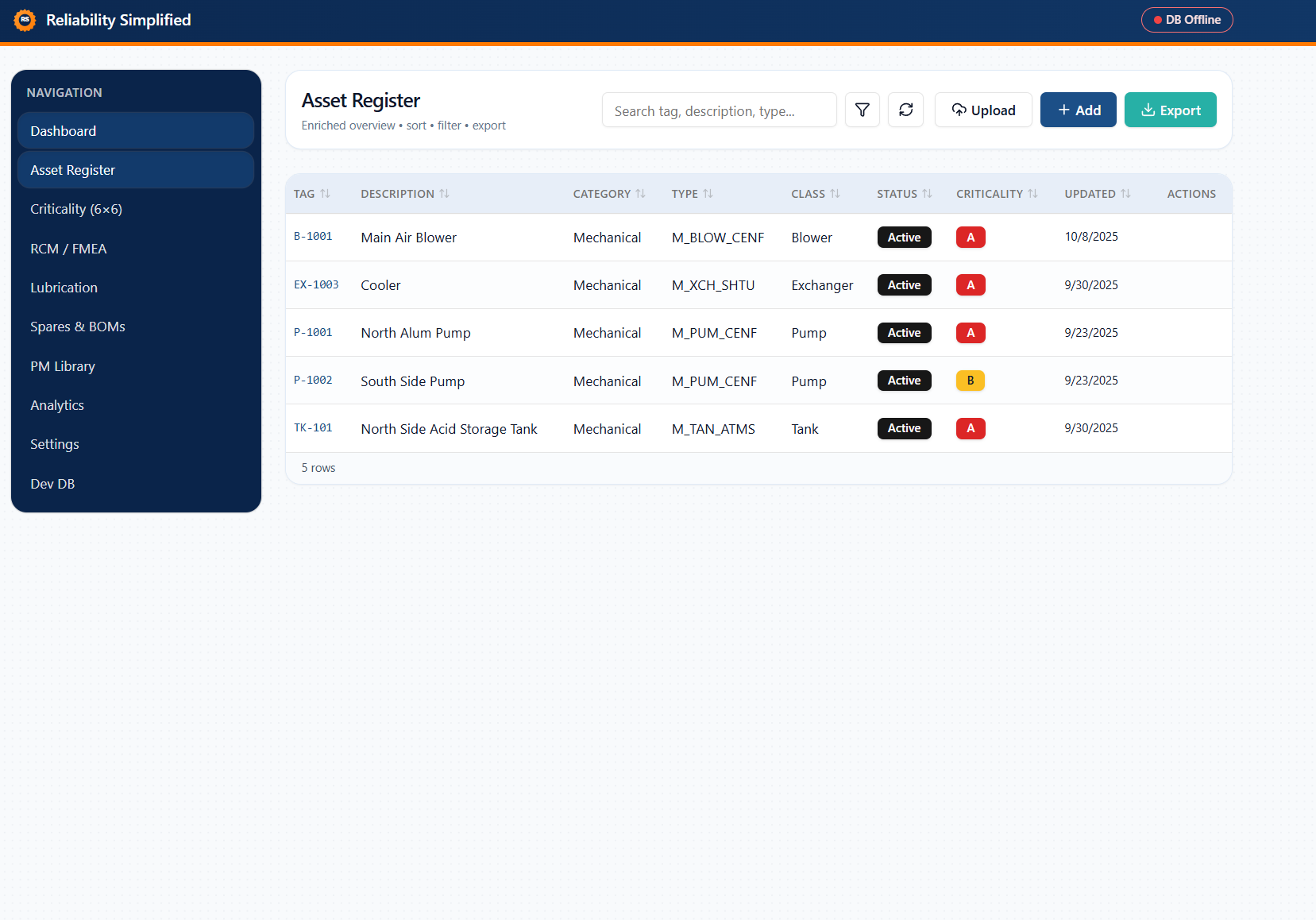

Reliability Simplified App

Standardize how you build asset lists, score criticality, run FMEA, and manage reliability actions—without messy spreadsheets or inconsistent methods.

- Asset registry + hierarchy + taxonomy

- Criticality scoring & heatmaps

- FMEA module and structured recommendations

Reliability Consulting

Bring in practitioners to accelerate rollout, align stakeholders, and turn the platform into a working reliability program—not a shelf tool.

- Asset strategy + hierarchy/taxonomy setup

- Criticality workshops with site teams

- FMEA facilitation + PM/strategy improvements

What the platform helps you do.

Build the asset backbone

Create a consistent hierarchy, naming, and minimum equipment context so reliability work is repeatable across teams.

Score criticality with confidence

Align maintenance and operations with defendable scoring—focus time and spend where it returns the most reliability.

Turn analysis into action

Use FMEA and structured recommendations to drive PM improvements, inspections, condition monitoring, and design changes.

Equipment Tags

Laser-engraved tags linked to asset records for fast field lookup. Scan to view criticality, notes, and key equipment details right from the shop floor.

Templates and tools built by practitioners.

Download practical templates, PM checklists, and FMEA worksheets—then use the platform (or our team) to standardize and scale those practices.

Start small. Scale fast.

Build your asset hierarchy and minimum equipment data in a consistent format.

Use criticality to align the team and target improvements that matter.

Run FMEA and apply recommendations to PMs, inspections, and reliability actions.

Outcomes teams care about.

Standard methods. Clear priorities. Better reliability decisions — without enterprise overhead.

One way of doing reliability

Stop reinventing formats and scoring. Get consistency across departments and sites.

Clarity for operations + maintenance

Make criticality and strategy decisions transparent so priorities don’t shift with personalities.

Better PMs and fewer surprises

Use FMEA-driven improvements to reduce reactive work and build a program you can prove.

Latest Insights

Practical lessons and case studies

-

Reliability Culture Starts on the Shop Floor: Why Discipline Beats Technology

The Myth of Technology in Reliability Walk into almost any refinery or chemical plant and you’ll find cutting-edge monitoring systems, advanced sensors, and expensive software platforms. From predictive maintenance dashboards to AI-driven analytics, the tools are everywhere. And yet — downtime persists. Failures still happen. Preventive maintenance…

-

Reliability – The True Cost of Cutting Corners

The False Reliability Economy of “Cheaper Is Better” It happens in plants and refineries around the world every day: a well-meaning procurement team chooses a lower-cost component or a generic spare over the OEM part. This can be the opening act to an expensive—and sometimes catastrophic—reliability failure,…